RECOMMENDED PRODUCTS

COMPANY PROFILE

Contact Supplier

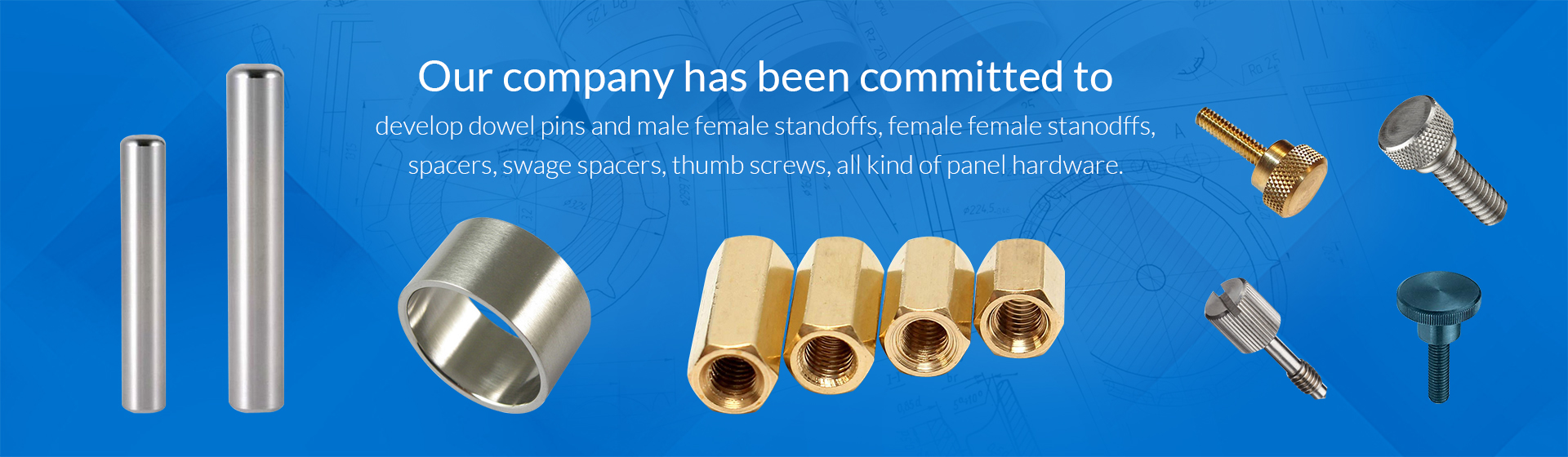

Shenzhen Long Wei Wang Precision Technology Co.,Ltd(Anliwei industrial (Hong Kong ) Limited) has been focused on the CNC high precision electronic hardware manufacturing for 20 years , With an area over 5000 square meters factory. We have strong R&D team, there is over 100 machines and measure equipment & tools which made in Japan and Germany. we specialized in manufacturing automatic lathe and CNC machining parts, Production process according to the ISO9001:2015 quality system . We offer OEM and ODM production by your drawing and sample. Our parts are widely used in automatic, Electronic Communications, Mechanical Engineering and tool area. We pursue customer first and high quality ,offer good service for you ,We are willing to cooperate with you and your company.

CERTIFICATES

Email to this supplier