News

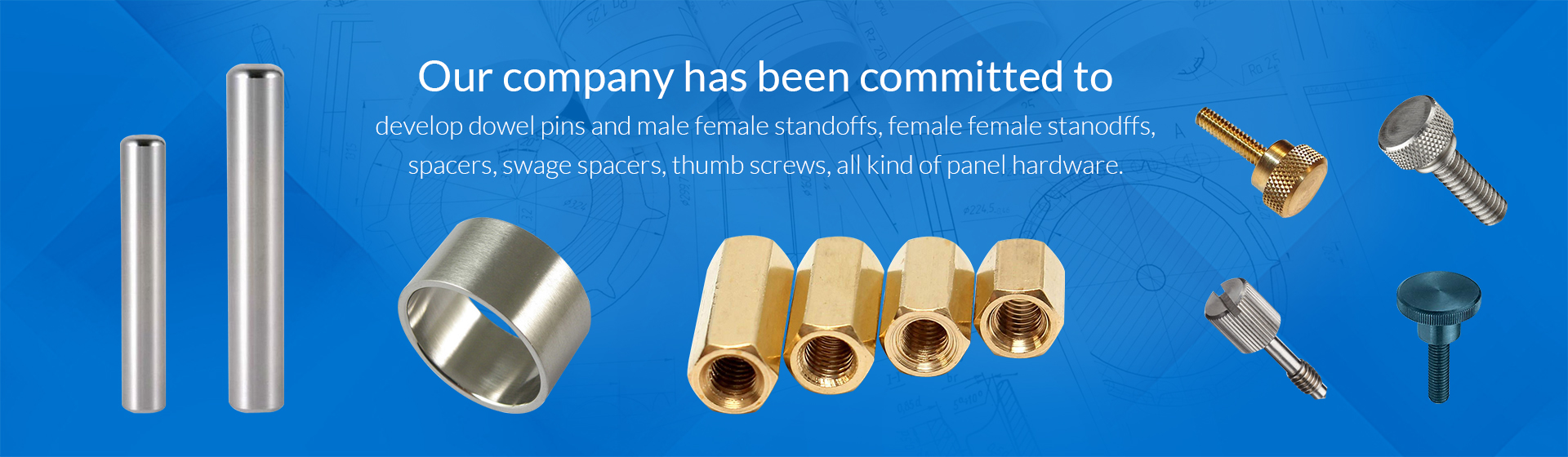

- Hardware product introductionOur company can make more product, you can refer the below, if you have interested, can contact us.

2019 03/25

- Stud heat treatment method for different materials and stud hardening processScrew heat treatment, we also call the stud. The stud are divided into steel and stainless steel stud. Iron is generally harder if it needs to be harder. All need to be hardened. But stainless steel stud rarely need to be hardened. Because its hardness is enough, it is hard enough. The iron heat treatment method for iron is described below. First, the heat treatment method: different heat treatment methods can be selected according to the object and purpose. Quenched and tempered steel: high temperature tempering after quenching (500-650 ° C) Spring steel: medium temperature temper after quenching (420-520 °C) Carburized steel: quenching after carburizing and then low temperature tempering (150-250 ° C) After the low carbon and medium carbon (alloy) steels are quenched into martensite, the general rule is that the strength decreases and the plasticity and toughness increase as the tempering temperature increases. However, due to the different carbon content in low and medium carbon steels, the tempering temperature has different effects on them. Therefore, in order to obtain good comprehensive mechanical properties, the following approaches can be taken separately: (1) Select low-carbon (alloy) steel, and after quenching, temper at a low temperature of 250 ° C or lower to obtain low-carbon martensite. In order to improve the surface wear resistance of such steels, only the carbon content of each surface layer is increased, that is, surface carburization is performed, which is generally called carburized structural steel. (2) Adopt medium carbon steel with high carbon content, and temper at high temperature (500-650 °C) after quenching (so-called quenching and tempering treatment), so that it can maintain sufficient strength under high plasticity, generally called This type of steel is quenched and tempered steel. If you want to get high strength, you would rather reduce plasticity and Resilience, for low-temperature tempering of gold-containing tempering with low carbon content, the so-called "ultra-high-strength steel". (3) Steel grades with carbon content between medium carbon and high carbon (such as 60, 70 steel) and some high carbon steel (such as 80, 90 steel), if used to manufacture springs, in order to ensure high elasticity At the limit, yield limit and fatigue limit, moderate temperature tempering after quenching is used. Second, the operation process: (1) Quenched and tempered steel: 1. Pre-heat treatment: normalizing->annealing (pearlite steel)->high temperature tempering (martensitic steel) (1) The purpose of normalizing is to refine the grains, reduce the degree of banding in the structure, and adjust the hardness to facilitate mechanical processing. After normalizing, the steel has equiaxed fine grains. 2. Quenching: The steel body is heated to about 850 °C for quenching. The quenching medium can be selected according to the size of the steel and the hardenability of the steel. Generally, water or oil or even air quenching can be selected. The steel in the quenched state has low plasticity and large internal stress. 3. Tempering: (1) In order to make the steel have high plasticity, toughness and appropriate strength, the steel is tempered at a high temperature of about 400-500 °C, and the steel which is sensitive to temper brittleness must be rapidly cooled after tempering to suppress tempering. Brittleness occurs. (2) If the part is required to have a particularly high strength, it is tempered at about 200 ° C to obtain a medium carbon tempered martensite structure. (2) Spring steel: 1. Quenching: oil quenching at 830-870 °C. 2. Tempering: tempering at about 420-520 °C to obtain tempered troostite structure. (3) Carburizing steel: 1. Carburizing: A type of chemical heat treatment in which a C element is infiltrated into the surface of a steel member in an active medium containing a certain chemical element at a certain temperature. Preheating (850 ° C) Carburizing (890 ° C) Diffusion (840 ° C) process 2, quenching: carbon and low alloy carburizing steel, generally using direct quenching or one quenching. 3. Tempering: low temperature tempering to eliminate internal stress and improve the strength and toughness of the carburized layer. The tempering temperature of the middle teeth of our company is about 360 °C, and the self-drilling screws (wall plate nails) have a tempering temperature of about 200 °C, and then cooled to 34-35 ° C and 39-40 ° C respectively. Screw hardening, screw heat treatment, general screw SMEs, there will be no self-heating factory of the enterprise. Generally, it is necessary to send it to a professional screw and hard factory. Therefore, our company that produces screws attaches great importance to the choice of heat treatment plants. To choose a reasonable price, the quality of the screw after heat treatment is high quality.

2019 03/22

- How to distinguish between single screw pump, twin screw pump and three screw pumpHow to distinguish single screw pump, twin screw pump and three screw pump: As the name suggests, a single screw pump is only a screw in the pump. Follow the habits of China's screw industry, naming, single-screw pump called the rotor screw, screw bushings called the stator. The special power driven by the external power source engages with the stator to form a sealed chamber that separates the suction chamber from the discharge chamber so that the pump can work effectively. At present, all kinds of single-screw pumps produced in various countries in the world engage the meshing pair formed by the rotor and the stator. Most of the products are also engaged by the single-head screwed rotor and the double-headed internal-screwed stator. In the recent ten years, some foreign manufacturers developed double-headed screw rotor and three internal-meshing helical stator meshing single-screw pump progressed rapidly, and some individual manufacturers have been the main exhibition to mass production and sales. A small number of manufacturing plants in China are also under development and are still in the development stage. Twin screw pump is a synchronous gear drive, connected to the two sets of spirals, no contact between the spiral, no mechanical friction, long service life. Three-screw pump is a screw-type displacement pump. In the triple-screw pump, due to the main screw and the driven screw on the spiral groove intermeshing and their three holes with the inner surface of the bushing to pump inlet and outlet to form a number of dynamic seal chamber, the dynamic seal Room will continue to move the liquid from the pump inlet to the pump outlet and step up the delivered liquid. Thus forming a continuous, smooth, axially moving pressure fluid. The liquid delivered by the three-screw pump is a lubricating liquid containing no solid particles, non-corrosive oil and the like oil and has a viscosity of 1.2-100 oE (3.0-760 cst). The high-viscosity liquid can also be transported by viscosity-reducing after heating. Not more than 150 ℃. Single screw pump is a rubber sleeve stator and rotor meshing, the use of transmission media lubrication, rubber sleeve caused by friction easily damaged, the general life expectancy of about six months, the transport of pure lubricative medium is more suitable, if impurities will greatly reduce the service life. However, its disadvantages are also obvious: the machining accuracy is higher, which increases the machining difficulty. In particular, the machining accuracy is not enough to affect the uniformity of the rotor and the stator, so that the above advantages no longer exist. Moreover, the machining time and the production cost Higher, this is why the current production less. Of course, it is also possible to manufacture a single-screw pump having a larger number of rotors and more stator spirals, such as a three-helix rotor and a two-headed helical stator. However, the manufacturing accuracy is higher and the flow rate is not always Increasing the number of spiral increases, it has no practical significance. Although this more helical head rotor and stator meshing pair has not been used in single-screw pumps, it has found wide application in the field of oil-mechanical screwdrivers.

2019 03/12

- Chinese Spring Festival was finish, our company start workChinese Spring Festival is too funny, so many interesting activity. Spring Festival is a traditional festival in China and some Asian nations. Because legend has it that the beast is afraid of red, afraid of fire and afraid of sound, so people will have couplets, firecrackers, gongs and drums and other customs. Different periods, different regions, different ethnic customs are not the same. The eve of the Chinese new year, people put on beautiful clothes, held a grand and grand "sorcerer". The boys dancing singing, in addition to the old and ushering in the new, the evil blessing. In the new year's morning, women would go back "auspicious water", I wish the new year Good luck and happiness to you. In China, the Spring Festival is also a minority national people's customs and festivals. People of all ethnic groups in accordance with their own customs, held a variety of celebration, with their strong national unique style.

2019 02/14

- PEM self-riveting threaded nutsThe unique design of PEM self-rive nuts, studs and fasteners published by Penn Engineering in the United States can be used for the assembly of sheet metal edges without compromising the matching sheet metal or fasteners. Its engineering design effectively shortens the minimum distance between the centerline of the hole and the edge of the sheet metal when riveting, providing an ideal solution when the fastener environment is limited. Once installed, the tough, durable and reusable metal threads are ready to be joined to other hardware, and can be repeatedly disassembled and re-disposed without affecting fastener or thread integrity, reliability and performance. Assembly. These rivet fasteners will eventually lock into a permanent assembly that will not spin, loosen, fall, or cause problems in action. The PEM SMPSTM self-rivet nut is made of highly corrosion resistant 300 series stainless steel and can be permanently mounted on (0.64 mm or thicker) ultra-thin steel or aluminum. Its smaller diameter (5.6 mm) and lower height (1.4 mm) provide a complete low head fastener product solution with the center of the fasteners closer to the edge of the sheet metal to 3.7 mm. Thread sizes range from #2-56 to #6-32, from M2.5 to M3.5. PEM FHLTM (steel) and FHLSTM (stainless steel) self-staking studs have a head that is not easily displaced, so the closest distance to the aluminum or iron plate edge can be increased by 50% compared to other standard products. At the same time, there will be no bulging at the edge of the sheet metal. The carrying sheet metal can also be as thin as 1 mm. Thread sizes range from #2-56 to #10-32, from M2.5 to M5.

2019 01/18

- Best Knurled Swage StandoffWe are Knurled Swage Standoff suppliers and specialize in Slotted Cup Head Stainless, Stainless Steel Knurled Swage Standoff, Back Face Knurled Swage Standoff, etc. The development of the company is inseparable from the trust and support of customers. If you have interested can contact us.Thanks

2018 12/21

- Machining of the CNCBefore using the MasterCAM software to automatically program the parts for NC machining, firstly, the machining process analysis of the parts is carried out to determine a reasonable machining sequence, while ensuring the surface roughness and machining accuracy of the parts. It is necessary to minimize the number of tool changes, improve the processing efficiency, and fully consider the shape, size and machining accuracy of the parts, as well as the rigidity and deformation of the parts, so as to finish the roughing and then finish the machining; Machining other surfaces after machining the datum. The knives used are external turning tools, 5mm wide grooving knives and external thread turning tools. The process flow of the part on the CNC lathe is: contour machining, grooving machining, thread cutting and final cutting. If the part is programmed with a cycle command, the program includes the following parts: 1) the coordinate system and the specified program of the machining process parameters; 2) the roughing and finishing process of the contour cycle; 3) the grooving cycle machining program; 4) the thread Cyclic machining program; 5) Final truncation machining program. Geometric modeling of parts When modeling the part, it is not necessary to draw the model of the whole part. It is only necessary to draw the outline of the machined part. The machining size, geometrical tolerance and fit tolerance can be omitted, which saves modeling time. , can meet the needs of CNC machining; when modeling, should be drawn according to the actual size of the part to ensure the correctness of the calculated tool path coordinates; and different processing steps can be drawn in different layers, With the function of the layer in MasterCAM, when determining the tool path, it is called or hidden to select the contour required for machining. Part machining tool path determination After the part is modeled, according to the arrangement of the machining process, select the tool used in the corresponding process, select the machining blank according to the requirements of the part, and correctly select the workpiece coordinate origin, establish the workpiece coordinate system, and determine the relative relationship between the workpiece coordinate system and the machine coordinate system. Dimensions, and various process parameters are set to obtain the tool path for part machining. The MasterCAM system generates the corresponding toolpath process data file NCI, which contains all the set tool motion trajectories and machining information. After the tool machining path is set, the machining simulation function provided by the MasterCAM system can be used to observe the cutting process. It can be used to check whether the setting of the process parameters is reasonable, whether there is interference in the actual machining of the CNC, and whether the operation of the device is correct. Whether the actual part meets the design requirements. At the same time, in the NC simulation processing, the system will give a report on the machining process. This can eliminate the trial cutting process in actual production, which can reduce material consumption and improve production efficiency. The MasterCAM system itself provides more than one hundred post-processing PST programs. For different CNC equipment, the CNC system may not be the same, and the selected post-processing program will be different. For the specific numerical control equipment, the corresponding post-processing program should be selected. After the NC control code generated by the post-processing is properly modified, if it can meet the requirements of the numerical control equipment used, it can be output to the numerical control equipment for CNC machining. Using MasterCAM software, it is easy to establish the geometric model of the part, quickly generate NC code automatically, shorten the programming time of the programmer, especially the NC program of complex parts, which can greatly improve the correctness and safety of the program, reduce the production cost and improve Work efficiency.

2018 12/10

- What's the Custom Hardware1.Male Female Standoffs China Male Female Standoffs manufacturer, choose the high quality Brass Hex Nut Spacer Standoff, Knurled Long Connecting Nut Standoff, Nylon Standoff Machine Parts, Brass Male Female Standoffs, etc. And we insist that quality is the point. 2. Standoff China Glass Standoff Provider, visit here to find the Oem Glass Standoff, Stainless Steel Glass Standoff, Glass Sign Standoff, Advertising Glass Standoff that you are searching for. Our product quality is absolutely guaranteed, allowing customers to rest assured that use. It is made of brass, low carbon steel, zinc alloy, stainless steel and other materials. The surface is plated with nickel, chromium or zinc. 3, CNC Custom Parts China Cnc Custom Parts manufacturers, welcome Cnc Machining Parts, High Precise Cnc Custom Parts, Stainless Steel Cnc Custom Parts purchasers from worldwide to visit our site. Our product quality is absolutely guaranteed, allowing customers to rest assured that use. 4, Automatic Lathe Custom Parts China Automatic Lathe Custom Parts manufacturers, Stainless Steel Cone Nozzle, Hydraulic Automatic Lathe Custom Parts, Stainless Steel Quick Coupling Connectors, Cnc Lathe Custom Electrical Parts, we offered that you can trust. Welcome to do business with us. If you need our products, please feel free to contact us. 5, PEM Standard Parts We are Pem Standard Parts leading supplier, our company offers high-quality Mini Pem Standard Parts, Pem Standerd Aluminum Parts, Custom Pem Standard Parts, Cnc Lathe Stainless Steel Parts, etc. Our product quality is absolutely guaranteed. If you need our products, please feel free to contact us.

2018 11/17

- The machining of iron parts in CNC machining parts center is good or badThe machining of iron parts in CNC machining parts center is good or bad. The machining center of CNC machining center is hard or good. It is a common workpiece. Many customers have not used machining center to process iron.This question is indeed a problem that many users will encounter when processing CNC machining centers. Today we answer this question and analyze the specific hard track. Before using the track, first as a CNC machining center manufacturer, you must ask what the iron parts the customer wants to process, how big the size is, whether it is finishing or roughing, etc. If you don't understand these details, even As a professional manufacturer of CNC machining centers, it is not good to give an accurate answer. Generally speaking, the iron parts that we often say are relatively large workpieces. Of course, we do not rule out special cases. Then we will use larger iron parts. The large-sized iron parts are of high quality, and the cutting amount is generally large. In this case, the hard rail is most suitable, the hard rail has good rigidity, strong earthquake resistance and strong bearing capacity, and is suitable for heavy-duty cutting. If you use a linear NC machining center, it is not very good, and even damages the guide rail. The rail is likely to be deformed due to the inability to withstand heavy-duty cutting. Therefore, when customers have special requirements, our CNC machining center manufacturers generally recommend customers to use hard-track CNC machining centers, and the same type of CNC machining center hard rails are cheaper than the line rails, and the CNC machining centers with large strokes are like The 850 and so on are all optional without line rails But, our factory can process any iron parts , if you have interested , can contact me.

2018 11/05

- Hardware industry has become more and more difficultWith the development of the company, the survival of the hardware industry has become more and more difficult. Therefore, we must focus on the quality first, quality assurance code. Make products that satisfy customers.

2018 10/05

- New:Custom Stainless steel 304 U clamp U boltCustom Stainless steel 304 U clamp U bolt Custom Stainless steel 304 U shap clamp U bolt are available in brass,steel,stainless steel and much more material. The size outer diameter 100mm, surface treatment according to the customer's needs ,it can be Zinc-plating, the heat disposing, black oxide coating, painting, powdering, silver plating, plastic, anodizing etc. This is our company's new product, new product discount, welcome to purchase

2018 09/19

- China's hardware and electromechanical industry entered the phase of newIn 2018, the current competitive landscape of China's hardware and electromechanical industry entered the phase of [middle and high-end brands". The brand at this stage was further refined into medium, medium, and high-middle and high-end market segments, and in the mid-market, it was mainly dependent on price war. , Operation is getting more and more difficult, leading many brands to start upstream development, and strive to obtain more brand value and development space. In 2010, it was a difficult year for China'sardware and electronic machinery industry. In 2018, it h was more difficult and complicated for the industry. Through research, we found that the increase in sales in the first quarter largely depended on the digestion of inventory. As for the double-digit increase in GDP in the first quarter, it cannot fully prove that the economy has steadily improved; although it maintained its sovereignty and independence in the exchange rate game with Americans, in the long run. Under such circumstances, China's hardware industry faces many challenges. In particular, for local hardware companies in China, it focuses on low-end and mid-to-low-end products. With lock prices as the main competitive means, the risk-resisting ability is not strong and the industrial concentration is low. . Even in this environment, there are still some new brands entering the market, showing the intense competition in the industry.

2018 09/06

- Gray cast iron processing tool materialFirst, gray cast iron processing tool material Although the application of nodular cast iron and vermicular cast iron is increasing, the application of grey cast iron is still strong. In the automotive industry, it will also continue to retain a large number of gray cast iron processing . However, the processing conditions today are different from those in the past. Due to the use of CBN tools, the cutting speed has increased by approximately 335 m/min compared to 10 years ago. The higher temperatures produced by high speed cutting may dissolve the coated carbide of the cutting insert in much the same way as the chemical reaction between the cubic boron nitride cutting tool and ferrite. Cast iron workpieces are hard and brittle. When turning cast iron workpieces, CNC blades need to withstand higher cutting heat and cutting forces. At present, the numerically controlled blades for turning cast iron workpieces are mostly carbide coated blades, and the coating thickness is generally 8 micrometers. 20-micron, coated CNC blades exposed the coating after fracture due to casting defects, revealing the alloy body, resulting in a low durability of coated carbide CNC blades turning cast iron workpieces. Second, ductile iron and vermicular cast iron machining tools Although polycrystalline cubic boron nitride tools have proven to be a superior cutting tool material, virtually unlimited tool life can be achieved when cutting grey cast iron. Unfortunately, when machining cubic ductile cast iron and vermicular cast iron with cubic boron nitride tools, they are affected by chemical dissolution. In these processes, the tool material interacts with the higher iron content in cast iron, which can cause rapid tool wear. This problem has driven the need to develop a tool grade that resists chemical action. CBN was developed based on the above ductile iron machining mechanism. It is commonly used in pearlite ductile iron high-speed cutting, such as QT500, QT600, QT700, QT800, QT900 and other high-strength ductile iron in the rough finishing. In order to process these new types of cast iron materials, it is required that the tools not only improve the wear resistance but also have very good toughness, and these two properties are difficult to achieve at the same time. In response to this challenge, many tool manufacturers are working hard to develop tools that provide the best combination of these two properties.

2018 08/27

- Harmonious and friendly electronic hardware trade teamOur company is a lovely family, colleague is very nice. At the last Thursday, our trading-team have a dinner So delicious

2018 08/20

- How to make you find you from a big crowdNowadays, online sales have become the trend of the times, especially in the fields of electronics and clothing. The share of online marketing has become more and more important, but in the traditional hardware and electronic tool industry, due to the quality of employees, corporate costs and The limitation of after-sales factors has been difficult in the field of online marketing, and its market share is far lower than other industries. So, how can the hardware and electronic tool industry practitioners do a good job in online marketing? The author started to contact the hardware and electromechanical tools industry in 2005, and engaged in network marketing in Zhejiang Yongkang and Shanghai for many years, so many of my friends asked me how to do a good job in network marketing. In fact, I think that network marketing is as simple as two points: Network marketing, to put it plainly, is to let your precise customers find you quickly and easily, and establish contact with you. Many people think that this is the way to fill in the company's contact information online: telephone, fax, mobile phone, email, etc. It is not. For a simple example, many companies hope that customers can find themselves on the Internet, all spend heavily on making their own corporate website or publish information on various BBS, blogs, and B2B/B2C websites. The result is not very effective. Because everyone used the wrong method, the result was less effective. The fact that companies release business information is not as good as it is because the company is pursuing value. If it pays too much and returns little, the investment is a failure. Therefore, before releasing information, it is very accurate Necessary, in the case of the hardware and electromechanical tools industry, it is best to publish corporate information on the corresponding e-commerce websites. Others, such as the hardware and electronic tools industry association portals or hardware mall portals of various manufacturers, and industrial websites such as: valve nets, building materials nets, valve nets, mechanical mould nets, auto parts nets, abrasive nets and so on. In terms of speed and convenience, first of all, businesses should take their own products into beautiful pictures that are consistent with product descriptions. It is best to attach information such as business licenses, organization code certificates, etc. Product name, model number, etc. Second, after the release of product information, we must continue to take the re-release. Because after you release the product, your peers are constantly releasing products, then your information will always be pushed back, and excellent network marketing staff will generally insist on publishing 20 to 30 different companies on each B2B site. Information, and persevere to these websites every day, retransmit 20 to 30 pieces of information in each station once (except weekends). In addition, you can also set up signatures, add links, publish some pictures, exchange more information, and improve shops from time to time.

2018 08/15

- What are the CNC Custom Parts machining?1. The customer can provide the drawing or give the product picture to us,we can use the CNC machining make it 2. Cnc Machining requiring high accuracy. The CNC machine tool has good rigidity, high manufacturing precision, precise tool setting, and easy size compensation, so parts with high dimensional accuracy can be machined. 3. Parts with small surface roughness. In the case of a fixed workpiece and tool material, finishing allowance and tool angle, the surface roughness depends on the cutting speed and the feed rate. 4. Parts with complex contour shapes. Any plane curve can be approximated by a straight line or an arc. The CNC machine tool has a circular interpolation function and can process various complicated contour parts.

2018 08/09

- Best Knurled Swage StandoffThe Knurled Swage Standoff are available in Aluminum ,Brass,Stainless steel, Steel materiall. The Hole Specifications Plain Swage Standoff – A plain swage standoff (no knurl) requires a STRAIGHT HOLE. The hole diameter in the board or panel is the same as the shank (or shoulder) diameter of the standoff with a tolerance of +.003″/-.000″ (+.076 mm/-.000 mm).

2018 08/08

- Our Company Hot Selling Aluminum Shoulder WasherThe Shoulder Washer are available in Aluminum, Brass, steel material . These washers provide good surface protection, deform slightly under pressure to partially seal and secure assemblies, and provide excellent thermal and electrical insulation for a precision product which is compatible with the rigid requirements of the Aviation, Military, Space, and Industrial Electronics systems. Shoulder Washer used wildly in Electronic .

2018 08/02

- Stainless steel CNC turning partsStainless steel CNC turning parts, Stainless steel machining parts, Stainless steel lathe machined parts,Stainless steel precision parts and so on. Custom Stainless steel material: SS316,SS304,SS303,SS416 etc stainless steel machining parts Stainless steel Machining parts can treatment as follow: Nickel plating, chrome plating, zinc plating, powder coating, polishing, sand blasting, brushing, etc Other finish are available as request. High quantites of production parts, innovative metal designs, can complete highly customized products, or basic standardized component utilizing our CNC machinery, advanced Engineers have applicable knowledge of critical and tight tolerance parts for the most stringent industries. We are always moving forward with the latest and most advanced technology so that we can fully to meet the high quality standards customers demand.

2018 07/24

- Custom PEM Standard PartsThe standard parts are products that meet the customer's requirements according to the item number given by the customer. We are PEM Standard Parts leading supplier, our company offers high-quality Mini Pem Standard Parts, PEM Standerd Aluminum Parts, Custom PEM Standard Parts, CNC Lathe Stainless Steel Parts, etc. Our product quality is absolutely guaranteed. If you need our products, please feel free to contact us.

2018 07/20

Email to this supplier